COMPLEX METALWORKING

Horlovka Metals metalworking company offers complete package of metalworking services: laser cutting, metal bending, robotic welding, powder coating, machining, assembly and design engineering services.

Horlovka Metals Ukraine is a Ukrainian subdivision of a Danish company N. Graversens metalvarefabrik A/S, operating in metalworking industry since 1955.

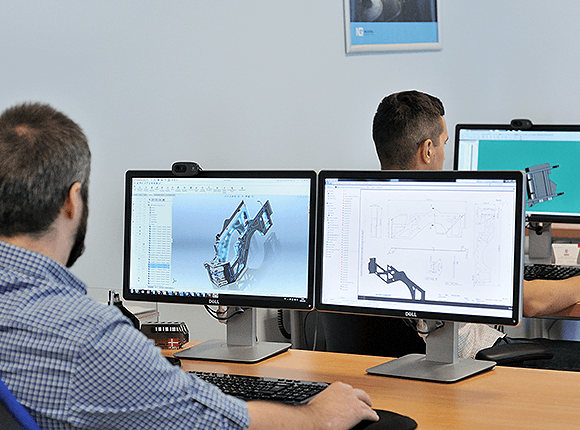

DESIGN ENGINEERING DEPARTMENT

-

Idea

You can start cooperation with Horlovka Metals with a mere idea or sketch, as well as a similar or old-style part.

-

Design Engineering

Computer 3D design and design engineering before the project launch

-

Ready Product

We will also give advice to your design engineers regarding capacities of our equipment and design peculiarities

SERVICES COST ESTIMATE

You can calculate a preliminary cost of laser cutting and bending services with a calculator, or our representatives will call you at any time convenient for you and provide comprehensive information.

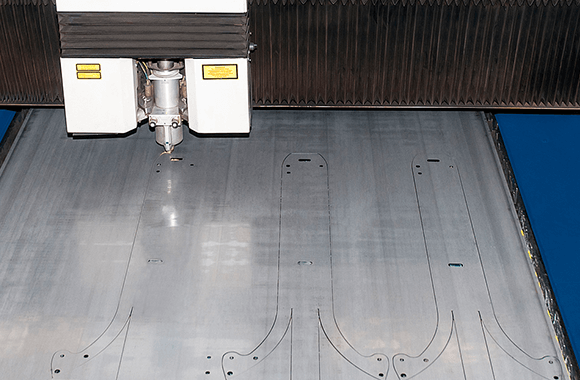

LASER CUTTING

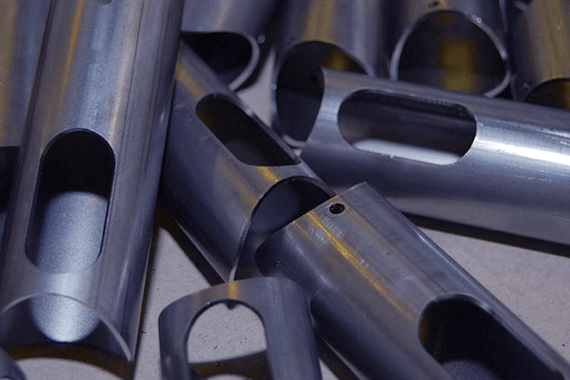

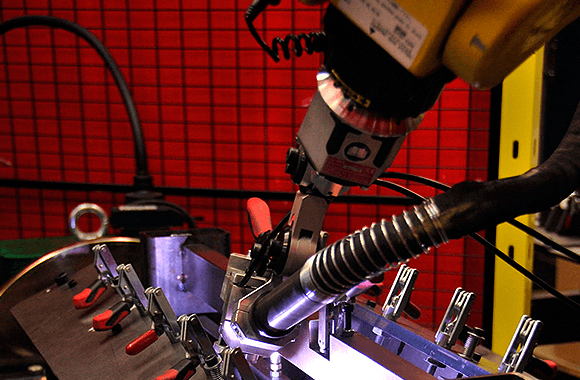

WELDING

QUALITY CONTROL AT ALL PRODUCTION STAGES

Horlovka Metals developed and introduced, pursuant to requirements of ISO 9001:2008 international standard, the system of quality control aimed at fulfillment of the customers’ demands and expectations, continuous improvement of all processes and services the company supplies and provides to its customers.

Horlovka Metals Ukraine uses up-to-date hydraulic plate-bending multiaxial machines with computer-aided calculation of parts position

We use modern high-velocity CNC centers,

produced by HEDELIUS (Germany) and MAZAK (Japan), and automatic material loader, produced by IEMCA (Italy).

Assembly works are included to the complex

of metalworking, but not provided as a separate service

Powder coating is ecologically clean, no-waste technology for obtaining decorative and decorative-protective polymer finishing with the up-to-date coating equipment. After coating, the surface acquires features, impossible to be achieved with convenient technologies. We use the modern equipment from the world leader in powder coating, Gema Switzerland GmbH, that ensures perfect quality of bend powder coating.

It is important for us to deliver completed orders to customers in a perfect condition. For this reason, our employees perform packing of all the products with the protective materials that suit for each element – film, pallets, foam. Each part has individual packing to avoid possible damaging during transportation.

We perform delivery of metal products with reliable cargo transportation companies we cooperate with for many years. The terms of delivery depend on the place of location of customer’s warehouse, dimensions of order, and preliminary agreement with customer.